Why Us

- Knowledge of the job: inside the plant and outside the premises.

- Liaison: with local communities and regulatory authorities.

- Genuine service with no run away attitude,

- Ownership and responsibility for all personnel sourced by us,

- Associates capable of handling any IR situation or technical challenge,

- Commitment towards all statutory and social obligations,

- Timely attendance to the service calls,

- Expertise in the activities taken over.

PUS started providing services from 1999. Right from that point of time, we grown in multiples, just because of our dedicated services and the smart work. Increase in business not only helped us to gain more revenue but also to adopt improved practices as we moved ahead. We feel that this growth is a product of our team’s continuous efforts and the support we obtained from our valuable clients.

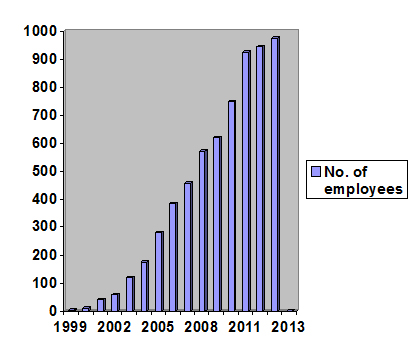

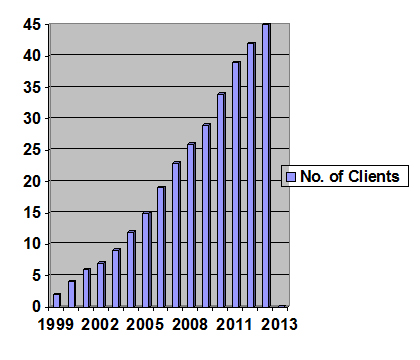

Following charts will give a bird’s eye view of our sustainable improvement of our firm

Chart no.1 is plotted between year (X-axis) and number of employees (Y-axis)

Chart no. 2 gives an idea about the number of clients (Y-axis) we managed to serve in respective year (X-axis).

01. ELECTRICALS :

a) Installations & Maintenance of Electrical Auxiliaries

b) Installations & Maintenance of H.T. sub stations

c) Installations & Maintenance / Operations of DG Sets.

d) Additional load demand applications & sanctions

e) Transformer filtration, oil testing,

f) Earthing testing, Megering of equipments,

g) Daily monitoring & Conservations of electricity through Proper selections of Electrical Drives,

h) M D control P.F. Control, Cut offs, etc.

02. CIVIL :

a) Building stability study & certification.

b) Architectural lay out & design of Industrial buildings

c) Acid Proof lining to reactors & flooring

d) Chemical leak proofing, Injection leak proofing etc.

e) Different type of painting with surface preparations

f) Civil layouts, building ( industrial / domestic ) constructions building strengthening, foundations, roof etc.

g) Hot / Cold insulations ( different type )

h) R.C.C. Constructions, Road Constructions.

i) Gardening

03. INSTRUMENTATIONS :

a) Timers & Installations

b) T.I. & T.I. C.S.

c) Flow meters

d) PID Controllers, proportional Controls, Pressure Cut Offs, Flow Switches etc.

e) PH Controllers, Multipoint Recorders

f) Level Indicators & Controllers

g) Pressure indicating controllers

h) Tank weighing, filling systems

i) Soft starters / drives

j) P & I Diagrams, Logics, Safety Interlocks.

04. ENVIRONMENT POLLUTION CONTROLS :

a) Effluent Treatment thro different type & stages

b) Noise Pollution Controls

c) Air Pollution Control thro’ different scrubbers & stack monitoring

d) Sold waste treatment, handling & disposal

e) Environment monitoring

f) Illumination systems

05. SAFETY:

a) Fire Extinguishers

b) Fire Control Systems

c) Hazop Studies

d) Hazardous chemical Handlings.

e) Explosive Chemical Precautions

f) Flame proof Area designs.

g) Safety appliances, Selections & applications

h) First Aids

i) Safety Audit

j) Safety manual

k) On site disasters control plan.

l) Safety week : Achieved No. of prizes.

m) Fire hydrant system / Network.

n) Rupture Discs, Air Curtains, Gas Handling Systems etc.

06. TOTAL QUALITY MANAGEMENT SYSTEMS :

a) Four basics of quality systems

b) Quality Circles

c) Quality Projects

d) Success Stories

e) ZDIP etc.

f) Z.D. day

07. GOVERNMENT LIASIONING :

1) Industrial Health & Safety Compliances

a) Pressure Vessel testing

b) Lifting tools & tackles

c) Factory building & layout approvals

d) Building stability Certifications

e) Safety audits & compliances.

f) On site / Off site disaster plans

g) Safety manuals & S O Ps

h) Fire extinguishers / Fire hydrant systems & layout studies & implementations.

2) Pollution Control Board:

a) Water consent & compliances

b) Air Consent & compliances

c) Solid waste handling & disposal

d) Yearly Audits & Return submissions.

e) Environment Impact Assessments ( EIA )

3) Explosive Licensing:

a) Petroleum Products License ( Class – A, Class – B, Class – C, )

b) Gas Storages

c) Explosives storages

4) Weights & Measures

5) Steam Boilers & Smoke Nuisances:

a) Boiler erections, Registrations, commissioning & steam testing, Operations

b) Efficiency studies,

c) Annual Inspections, IBR repairs & Piping, Stress analysis,

6) Electrical Installations Inspections

a) D.G. Installations, Operations, maintenance,

b) Substation erections, maintenance,

c) Lifts & Hoists,

d) EOT cranes, erection, maintenance

e) MCC installations, Cabling

f) Power plants: Captive, Co-generation

7) Quality Management system : ISO – 9001 : 2008

a) Basic & Clauses, Lists, Formats, Work Instructions, Procedures, Records,

b) House Keeping

c) Internal Audits, NCRs, Corrective & preventive actions,

d) Trainings, etc.

e) M.R. Records.